The increasing use of plastic components as a cost-effective light weighting solution for a range of applications, including automotive but also packaging and general industry, is expected to lead to continued growth of the plastic injection moulding industry, Industeel offers one of the widest product ranges for Mold Tool and Die Steels, in terms of number of grades, thickness range from 6 mm to 1100 mm and width from 1 meter wide to more than 2 meters wide, in both rolled and forged plates.

Industeel provides worldwide solution steels for Mold construction such as pre-hardened alloy steels, stainless steels for cavities, extrusion dies and mold bases, hot work steels for plastic, forging and die casting applications as well as cold work steel for press tools, progressive dies, stamping dies and cutting tools.

Industeel has also developed its own brands of steel in every sector of this industry, in order to offer tailor made solutions with improvement from generic grades in terms of machining, tool life time, repairability, thermal conductivity, through-hardness and improved mechanical properties. Brands like Superplast® family steel, Mecasteel, Isotrop, Tenasteel are well known all over the world for such demanding applications.

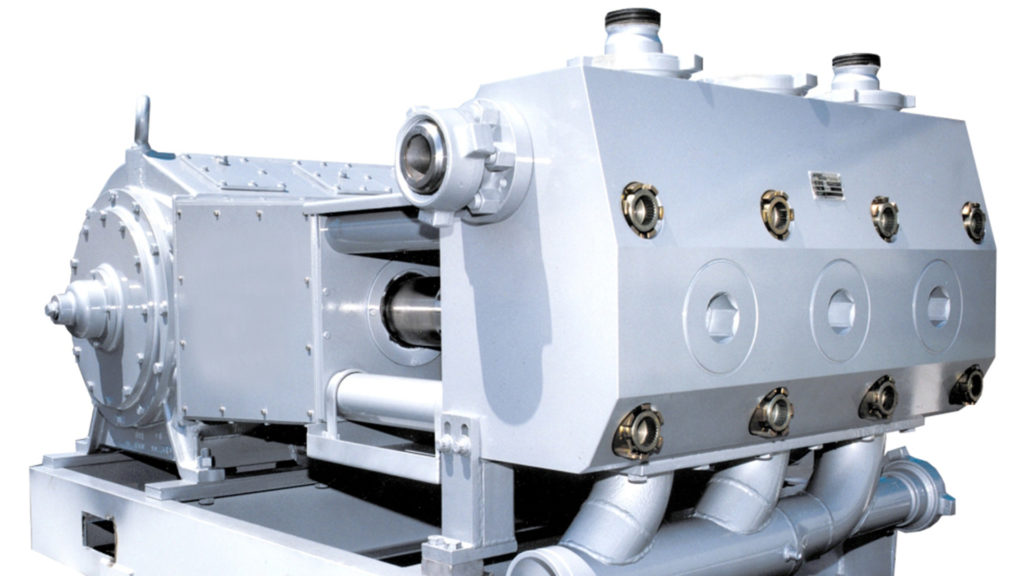

Mechanical engineering typically requires the use of thick wall plates and blocks for machinery such as mechanical or hydraulic presses, counter-weights, press brakes, ball mills, magnets and other examples of heavy machinery. Typically, these applications will require weldable steels with uniform mechanical properties through the plate thickness. Industeel can provide such steels as conventional plates, but also as flame-cut pieces according to customer drawings, with excellent tolerances on the flame-cut surfaces.