New metallurgical concept combining 600 HB hardness level with excellent ductility and toughness close to a 500 HB material. Ultra-High-Hard Armor steel with very high ballistic performances and integration possibilities

First multipurpose 600 HB with an impressive ballistic behavior in terms of deformation capacity, resistance to multi-impacts and and best in its class workability (mainly bending)

Mars® 650 is a ultra-high-hard (typical 650 HBW) protection steel offering uncompromising ballistic resistance performance, for use as add-on armor when weight reduction is essential.

Easy integration in multi materials and composite solutions with its incredible flatness of 3 mm/m

Mars® 650 is a ultra-high-hard (typical 650 HBW) protection steel offering uncompromising ballistic resistance performance, for use as add-on armor.

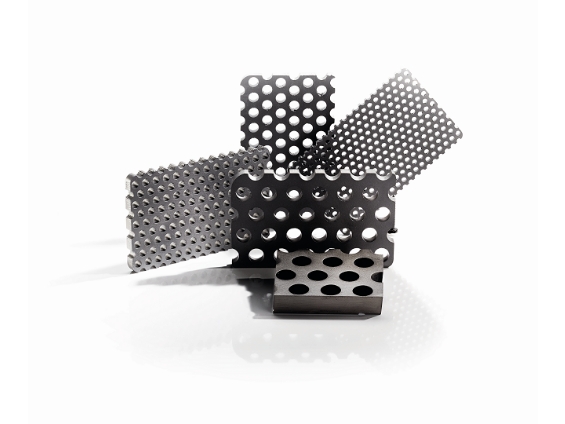

In the perforated version, holes are evenly distributed within the surface to interact with the diameter of the incoming threat. The use of specific perforation process leads to very good flatness, absence of HAZ and low residual stress.